Custom Heated Hoses

Custom heated hoses are designed to maintain fluid or gas temperatures during transfer. They offer tailored heating, insulation, and flexibility for various industrial and commercial applications.

Custom Heated Hoses build to order

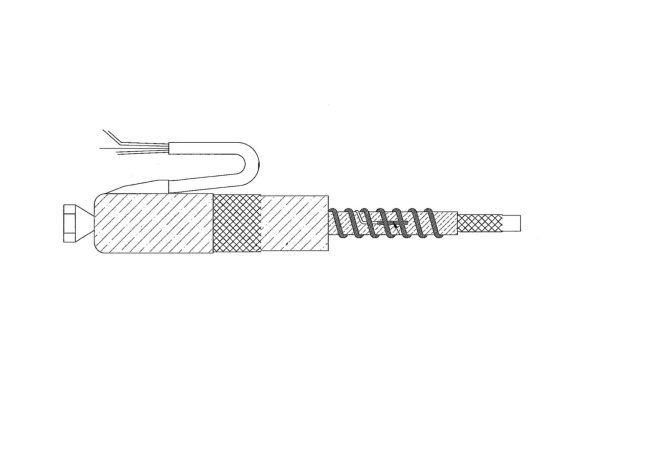

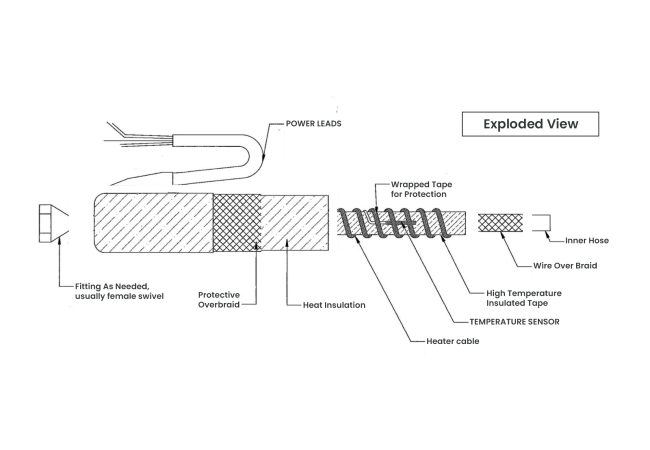

The labeled diagram represents a typical example of the flexible heated hoses we supply. However, we take pride in offering a tailored service and an objective approach to each customer’s specific requirements. For this reason, we avoid defining any single construction as a “standard” flexible heated hose, instead providing a variety of options to suit each unique application.

The diagram also reflects the current stage of our manufacturing process. As a forward-thinking and innovative company, we are constantly exploring new advancements in both materials and production techniques. We therefore reserve the right to amend or enhance any of the features described in line with ongoing development.

British made and Guaranteed

All heated hoses are built to our well-proven design, using our purpose-developed equipment at our own factory in the West Midlands. We operate strict quality control at all stages, and all our heated hoses are fully tested and guaranteed for twelve months.

Although we have built up a fund of experience, all our heated hoses are treated as specials, and they are designed to suit individual requirements and equipment. We pride ourselves on our quick response, as heated hoses can be built, tested, and delivered within days rather than weeks.All our heated hoses MUST be connected to a suitable temperature controller, otherwise damage will occur. Temperature controllers for all types of applications can be specified and supplied, either with the heated hoses or separately.

heated hose applications

Hot melt machines, wax transfer systems, and polyurethane foaming equipment are widely used in various industrial processes. Insulated glass machinery plays a vital role in the construction sector, while gas analysis measuring equipment ensures accuracy and safety in monitoring operations. Chemical dosing systems are essential for controlled applications, and bitumen transfer along with heavy fuel oil systems support energy and infrastructure industries. In addition, food treatment and transfer systems are crucial in maintaining quality standards in the food sector, whereas packaging equipment provides efficiency and reliability in product handling and distribution.

Features of Heated hoses

- Good temperature stability and heat distribution.

- Bespoke manufacture to customer’s specification or existing pattern.

- Built to withstand high temperatures and pressures.

- Suitable for liquid and gas transfer.

- Energy-efficient heating system reduces operational costs..

- Flexible and durable design allows easy installation and handling.

- Custom-made to meet customer specifications and industry requirements.

Application Examples

- Equipment for accurate monitoring and evaluation of different media.

- Machines for melting and applying adhesives or coatings..

- Built to withstand high temperatures and pressures.

- Used for producing durable polyurethane foam for various applications.

- Equipment designed for heating and handling bitumen.

- Systems for melting and transferring wax efficiently.

- Solutions for safe transfer and use of heavy fuel oils.

application in general

Our heated hose systems are designed to provide reliable frost protection for different media and to prevent condensation during operation. They ensure that liquids or gases are maintained at their required working temperatures, supporting efficiency and safety. These hoses are also ideal for the transportation of gas samples from the measurement point to an analyzer, guaranteeing accurate results. Additionally, they enable the smooth transfer of high-viscosity materials in a fluid state and are essential for applications where maintaining specific temperatures is critical to the fabrication process. Furthermore, their flexible design allows for easy mobility, making them suitable for use with mobile supply stations where transportability is a key requirement.

Material

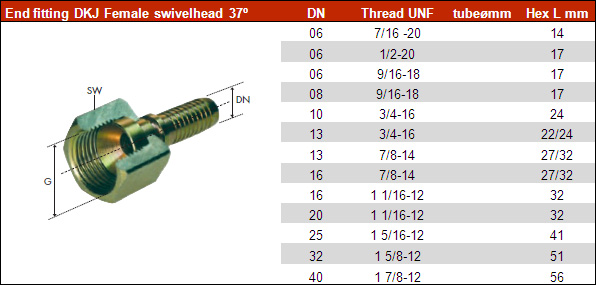

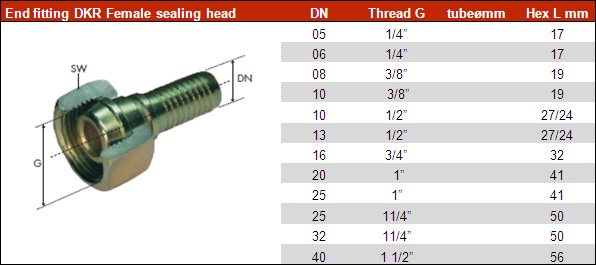

Our equipment is available in a range of high-quality materials to suit different applications and operating environments. Standard options include stainless steel for durability and corrosion resistance, as well as steel bichromate coated for added protection. In addition, special materials and fittings can be provided upon request to meet specific requirements, ensuring flexibility and reliability for a wide variety of industrial uses.

Standard and Custom Technical Specification

- Length: Manufactured to desired specification.

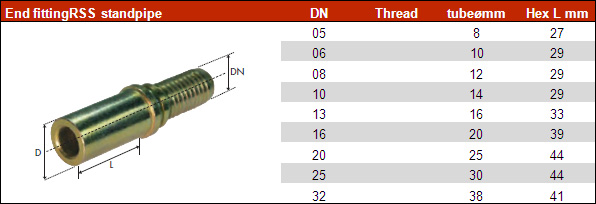

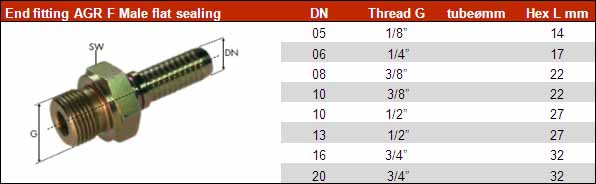

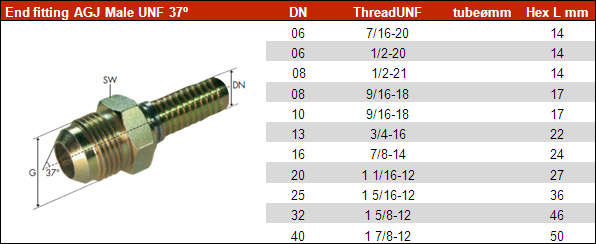

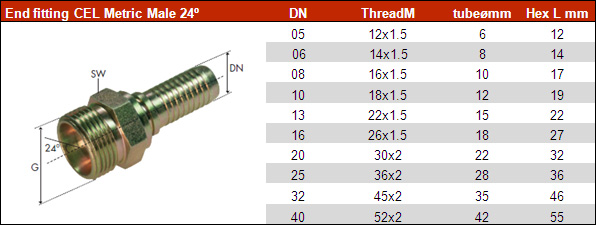

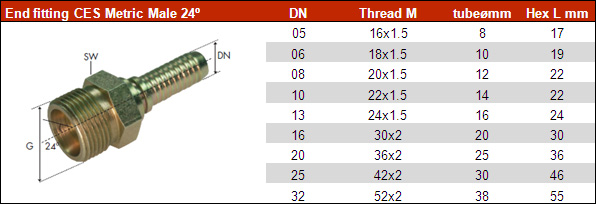

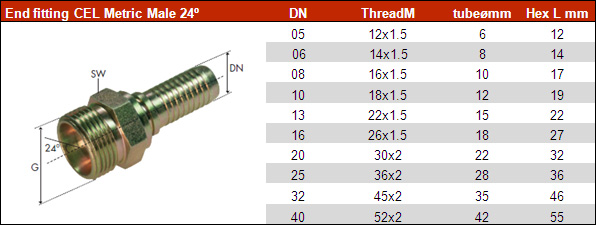

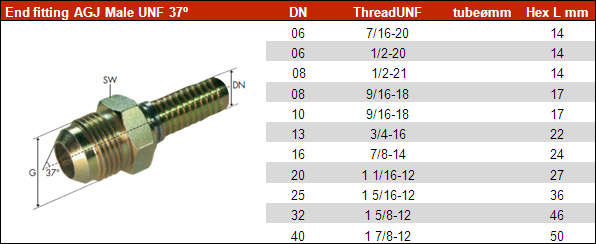

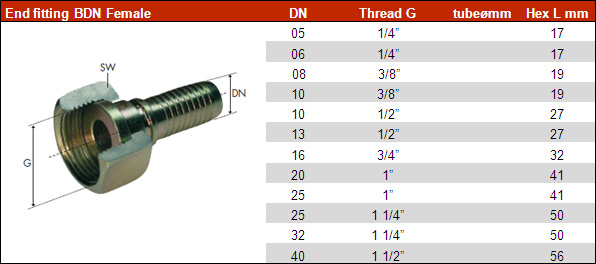

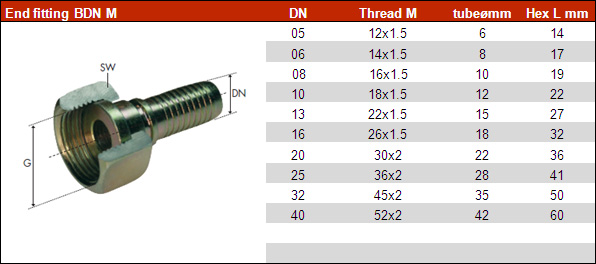

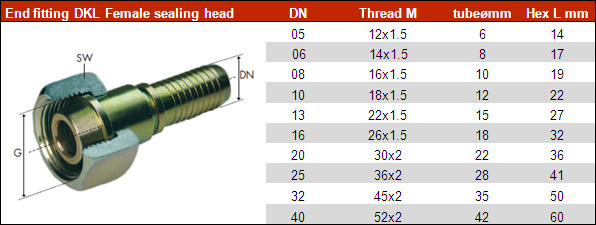

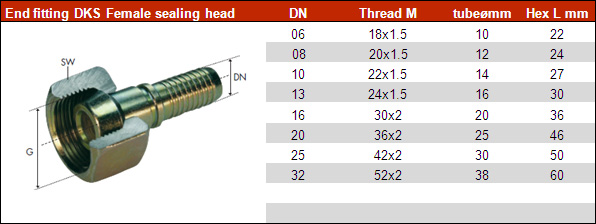

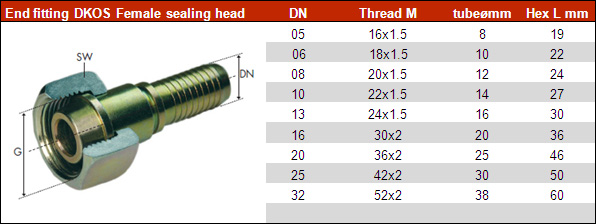

- End fittings: A variety of swaged fittings to suit most pipe thread systems, supplied in a range of materials.

- Bore size: Sizes to suit customer’s specifications can be supplied.

- Pressure Ratings: Wide range of pressure rated hoses to suit your application.

- Temperature sensor: PT100, J, K and Thermocouple types of sensor can be supplied. other types may be available, by prior consultation (Other types to customer requirements).

- Heater: The heating element is insulated with a layer of silicone rubber for moisture protection. Hazardous Area elements are also available.

- Thermal insulation: Layers of glass fibre insulation.

- Outer options: Black polyamide sleeve braiding or wash down heat-shrink.

- End caps: Moulded silicone rubber caps are used exclusively.

- Voltage: To customers requirements.

- Electrical/Options: The temperature sensing and heating wires are standard, but additional wires and/or tubes can be incorporated into any build, if necessary, to control customer operation or to feed additional equipment.

Get in touch to see how we can work together

Simply fill out our form with a few simple details and we will get in touch asap

In Business for

over 30 years.

In Business for over 30 years.